The Revolution is Here: Why CNC is Non-Negotiable

The modern woodworking landscape is being shaped by speed, precision, and efficiency. For your woodworking business to thrive and scale, moving beyond traditional methods is essential. A Computer Numerical Control (CNC) router is the powerhouse that transforms a digital design into a perfect physical product—but choosing the right one is the single most critical investment decision you will make.

At Kataria Tech Zone, we understand that every woodworking business has unique needs, from a custom cabinet shop to a high-volume furniture manufacturer. This guide breaks down the essential factors to ensure you select a CNC router that is not just a purchase, but a catalyst for growth.

1. Work Envelope: Sizing Up Your Success

The first and most fundamental question is: How big are the parts you need to cut? The working area (or ‘work envelope’) of your CNC router dictates the maximum size of your projects.

- Small to Mid-Size Shops (Signs, Inlays, Custom Furniture): A machine with a working area of 2′ x 3′ or 4′ x 4′ might be sufficient. This is ideal for smaller, intricate parts or hobby-grade production.

- Cabinet Making & Sheet Goods (High-Volume): If you process standard sheet goods (like a 4′ x 8′ sheet of MDF or plywood), you absolutely need a 4′ x 8′ (or 1300mm x 2500mm) machine. This allows for nesting—the practice of efficiently arranging all parts on a single sheet to minimize material waste—a massive profitability booster.

- Rule of Thumb: It is almost always better to choose a machine slightly larger than your current needs, as expanding the machine’s work area later is often impossible.

2. The Heart of the Machine: Spindle Power & Rigidity

The spindle is the router’s engine. Its power and the machine’s overall construction determine your cutting speed and the quality of the finish.

| Factor | What it Affects | Recommendation for Production |

| Spindle Power | The speed and depth of cut you can achieve, and how long you can run the machine continuously. | 3.0 kW to 6.0 kW (or higher). A higher power spindle (e.g., 4.5 kW) is necessary for non-stop, heavy-duty processing of hardwoods or sheet goods. |

| Machine Rigidity | Accuracy, vibration control, and longevity. A powerful spindle on a flimsy frame is useless. | Look for heavy-duty steel gantry and frame construction and high-quality rails/bearings. Rigidity is what allows you to use that high spindle power effectively. |

| Tool Holding | How securely the bit is held. ER Collets (e.g., ER20, ER25) are standard for high-precision, industrial spindles. |

3. Maximizing Throughput: ATC vs. Manual Tool Change

Tool changes are necessary when a job requires different bits (e.g., a large bit for roughing, a small bit for detail, and a V-bit for engraving).

Automatic Tool Changer (ATC) CNC

- Pros: Unmatched Efficiency. The machine automatically swaps tools from a rack, allowing for lights-out or unattended operations. Massively increases productivity on multi-tool jobs.

- Cons: Higher Upfront Cost. ATCs add significant cost, complexity, and require an air compressor system.

- Best For: High-volume production shops, cabinet manufacturers, and businesses where every minute of machine time counts.

Manual Tool Change

- Pros: Lower Cost and Maintenance. A great starting point for smaller budgets.

- Cons: Requires an operator to manually stop the machine, change the bit, and re-probe the Z-height for every tool change. This adds significant downtime.

- Best For: Entry-level businesses, custom one-off projects, and shops on a tighter budget.

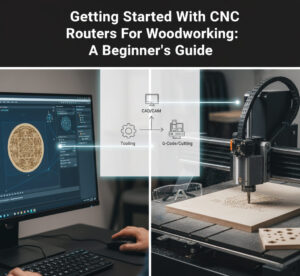

4. The Brain: Software (CAD/CAM) & Controller

Your software is what translates your design idea into machine instructions (G-Code).

- CAD (Computer-Aided Design): Used to create the 2D or 3D model (e.g., AutoCAD, Fusion 360).

- CAM (Computer-Aided Manufacturing): Used to generate the toolpaths (e.g., VCarve Pro, Fusion 360).

- Crucial Feature: Ensure your CAM software supports True-Shape Nesting if you plan on cutting full sheets for cabinet parts.

- Controller: The interface that runs the machine (e.g., Mach3/Mach4, Syntec, DSP handle). A user-friendly, reliable controller is key to minimizing frustration and downtime.

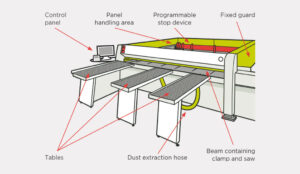

5. Workholding: Keeping Material Secure

A secure hold is essential for accurate cuts and operator safety.

- Vacuum Table: The gold standard for production, especially for sheet goods. A powerful vacuum pump holds the entire sheet down instantly, saving hours on clamping. Highly recommended for 4′ x 8′ nesting machines.

- T-Slot or Clamp System: Versatile for oddly shaped pieces or thicker slabs. Uses mechanical clamps. Requires more time to set up for each job.

Take the Next Step with Kataria Tech Zone

Choosing the right CNC router is the difference between a high-growth business and a costly mistake. Don’t navigate this complex decision alone.

At Kataria Tech Zone, we specialize in providing tailored CNC solutions, from entry-level precision machines to industrial-grade Automatic Tool Change routers designed for all-day production. We can help you analyze your current workflow and future goals to find the perfect machine specifications.